| Unit Price: | USD 2000000.0000 - 20000000.0000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Condition: New

Voltage: 380V

Paper Trim Width: 1575~6000mm

Weight: 100~2000Ton

Pulping Type: Mechanical Pulp

Bleaching: Unbleached

Additional Info

Packaging: Wooden package

Productivity: Above 100Ton/Day

Brand: Tianshin

Transportation: Ocean

Place of Origin: China

Supply Ability: 4 sets per year

Certificate: ISO2000

Port: DALIAN,CHINA

Product Description

Pulping Machinery For Making Straw Pulp

Self-regulating pulping and its equipments

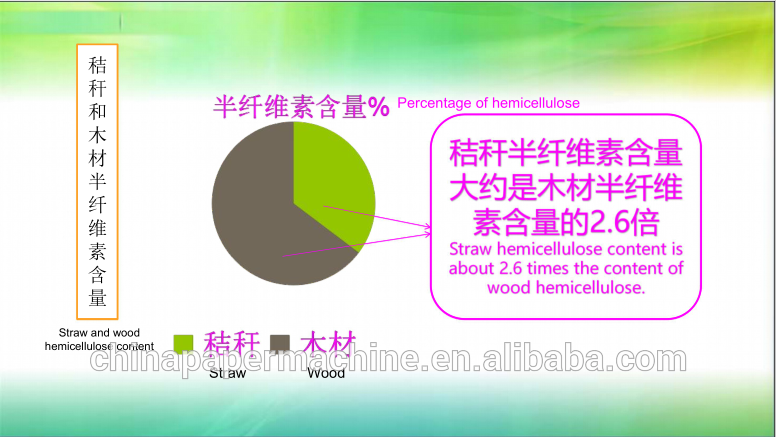

This is pulping machinery for making straw pulp, rice straw pulp and bagasse pulp etc.

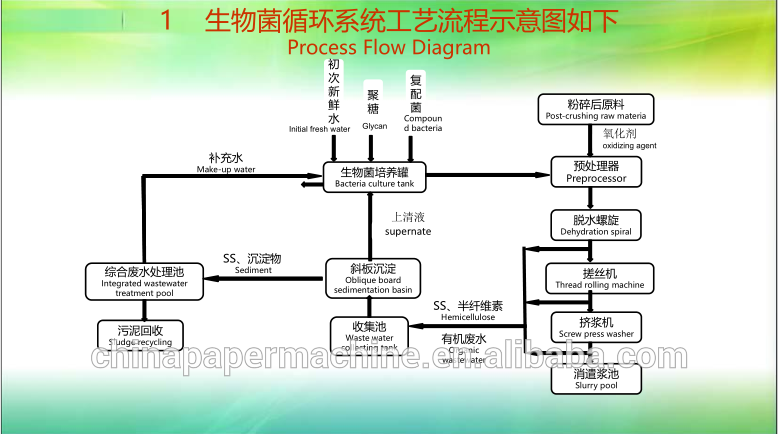

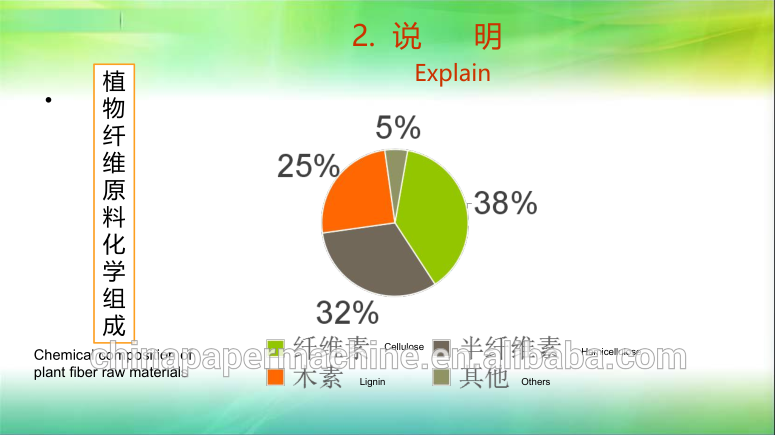

The lack of paper making raw materials is a common problem, the use of seasonal growth plants or wild trees etc for the paper pulp is an effective solution.However, using this material pulping will produce a lot of black liquor containing inorganic compounds, how can get more fiber pulp, low investment to processing black liquor which can let it reach the water recycling or reach the discharge standard of environmental protection, it has been a worldwide problem all the time.

For decades, we have carried on the laboratory experiment repeatedly on all kinds of materials of pulping method, and successfully carried through serialization volume production in pilot plant for cotton straw, rice straw, reed, and bagasse etc as raw material for pulping system, satisfactory results has been achieved.

Our new pulp-making process system has the following features:

1. According to different raw materials, we use self-made raw materials roughing filtering equipment for filtering, removing of large amounts of fiber miscellaneous.

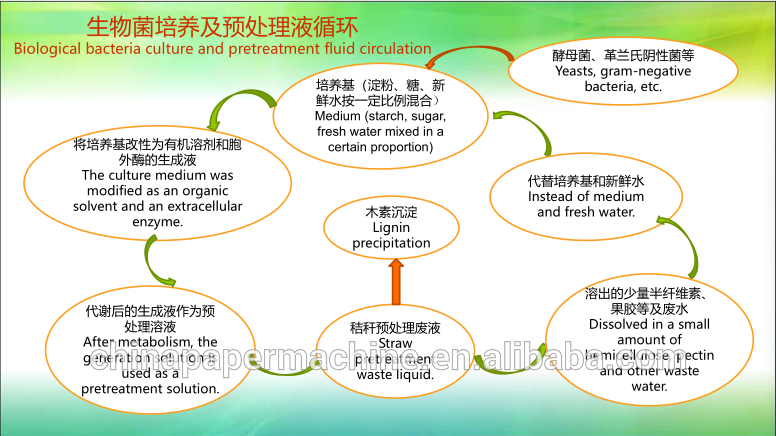

2. Selectivity dissolving out the main elements which can produce black liquor, both of fibers` utilization and original color pulp`s quality can be taken into consideration.

3. Strong alkali and strong acid chemicals will not be used in this pulping process, which will reduce the black liquor treatment equipment.

4. Water saving and emissions reduction, biogas generated from the water treatment process will be usde for electricity generation, the sludge can be used as organic fertilizer.

5. The utilization rate of raw materials converted into a finish pulp can reach 70% above.